How to make the most of your drone inspections in 2019

More than 20,000 drones are registered for commercial use according to the United States Federal Aviation Administration (FAA). The most prominent commercial application for drone technology is infrastructure maintenance and monitoring, an industry with a projected value of $45.2 bn worldwide according to PricewaterhouseCoopers (PWC). However, this application of drone technology is mired with potential inefficiencies and logjams, as drones collect up to thousands of images per inspection. The task of sorting through photographs and translating them into actionable data on defects and repairs can be tedious and hinder your ability to effectively scale drone inspections in 2019.

After extensively discussing drone data analysis with industry experts at conferences and events such as the Energy Drone Coalition & Commercial UAV Expo, the NAR team learned that companies continue to rely on antiquated or inefficient techniques to analyze drone data, a process that wastes both time and money. Common industry practice entails examining a generated 3D model manually, watching hours of videos, and/or sifting through thousands of pictures. This analysis is often conducted at an office following a field inspection, where thousands of images, sometimes garnered from multiple inspections, run the risk of being misorganized. Such a workflow requires that a significant amount of effort be spent on cleaning, sorting and analyzing data to ultimately create an inspection report, posing a series of broad problems for companies:

- Inefficiency: Wasting three days to three weeks on analysis, limiting the efficacy and widespread use of drones in inspections

- Inaccuracy: Detecting defects smaller than two centimeters is difficult (assuming a decent camera resolution of 5280×2970) when using 3D models as it is recommended that a drone fly far from the asset, generally at more than 75 feet away

- Cost: Contracting data management services or hiring a dedicated workforce to manage & analyze data comes at a high cost. With firms doubling or tripling their drone inspections in the coming year, expenditures on data analysis present a serious concern

Traditional on-site inspections produce same-day reports under the supervision of a certified engineer who is responsible for identifying structural deficiencies, normally by taking photos and making corresponding notes. But this seemingly more efficient method lacks the detail and breadth that modern drone technology offers. NAR seeks to both harmonize these methods as well as streamline the reporting process through mitigating the hassle of managing vast amounts of data while retaining all practical aspects of real-time inspections.

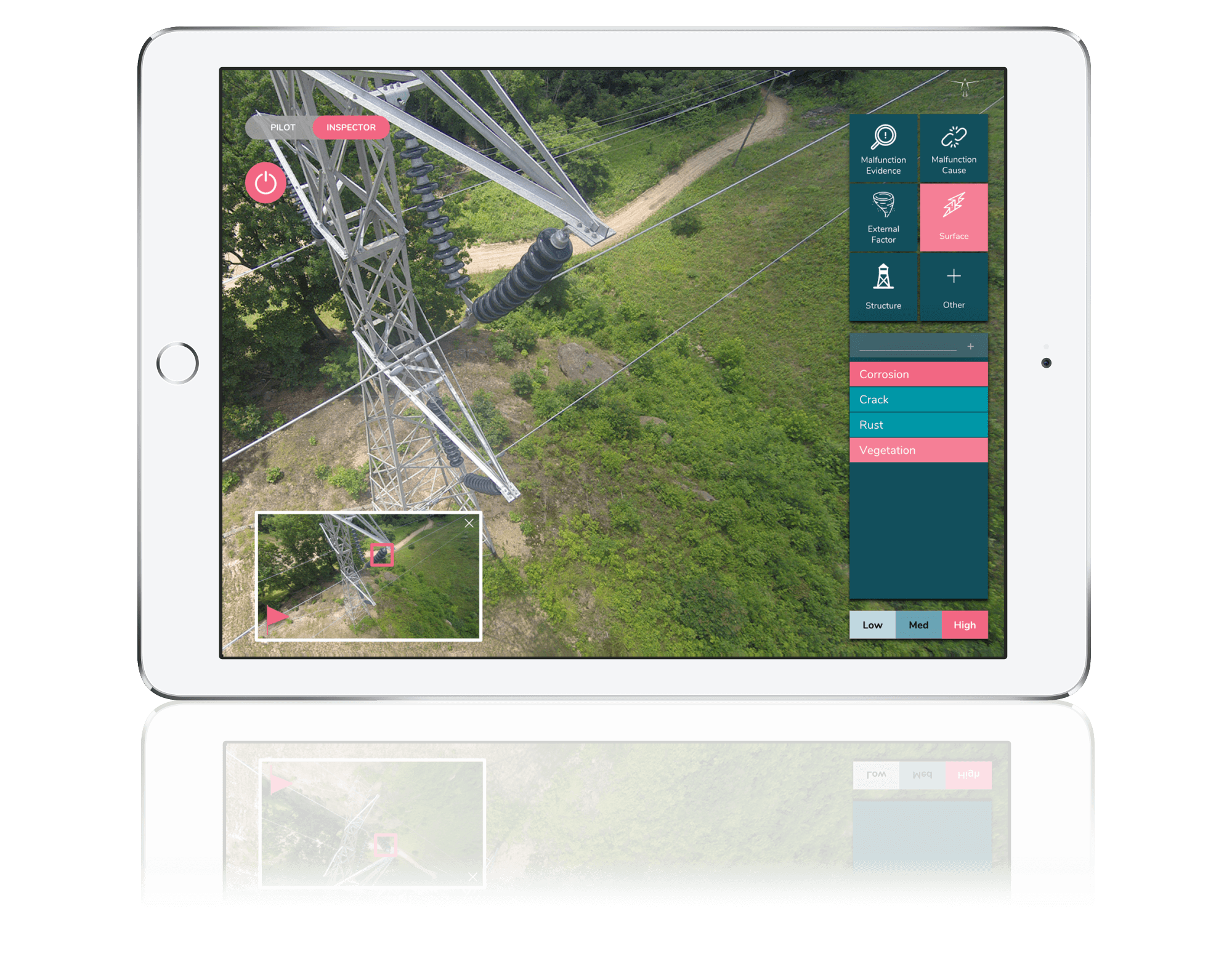

NAR is a tablet-based application that functions with your drone, enables you to log defects as a drone inspection is being carried out, and instantly generates a professional report upon landing. These reports contain high-quality images of logged observations – specifically their types and location – whether one is inspecting a bridge, building, transmission line, wind turbine, or any other structure.

NAR seeks to close the gap between the cutting-edge technology employed to carry out inspections and the antiquated and inefficient techniques used for analysis and reporting by transforming the drone from a flying camera into the ultimate inspection tool. We invite you to try NAR for free today.